A Comprehensive Guide to Tools for Cutting Foam to Size in the Bedding Industry

Share

Table of Contents

- Introduction

- Saws for Foam Cutting

- Band Saws

- Oscillating Blade Cutters

- Blades for Foam Cutting

- Teflon Coated Blades

- Carbide-tipped Blades

- Toothed Blades

- Other Essential Tools

- Measuring Tapes and Rulers

- Marking Tools

- Workbenches

- Safety Gear

- Conclusion

Introduction

If you're in the bedding industry and specialize in made-to-measure mattresses using materials like Reflex foam, memory foam, or other types, you're aware that precision and quality are key. To achieve these, having the right tools for cutting bed foam to size is crucial. This guide outlines the types of saws, blades, and other essential tools, along with an idea of the costs involved, especially when purchasing second-hand machinery.

Saws for Foam Cutting

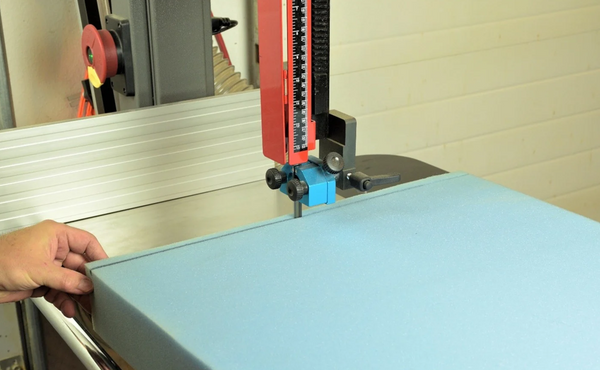

Band Saws

Cost: Second-hand prices can range from £500 to £2,000.

Usage: Band saws are versatile and ideal for making irregular cuts. They are also good for foam blocks that are particularly large.

Oscillating Blade Cutters

Cost: Prices for second-hand units range from £250 to £600.

Usage: Best for small to medium-sized operations, these tools offer precision but might not be the best for larger blocks of foam.

Blades for Foam Cutting

Teflon Coated Blades

Cost: Around £20 to £50 each.

Usage: These blades reduce friction and provide a smoother cut, often used in band saws and oscillating blade cutters.

Carbide-tipped Blades

Cost: £30 to £100 each, depending on size.

Usage: They last longer than steel blades and are commonly used in more industrial settings.

Toothed Blades

Cost: £15 to £40 each.

Usage: Good for rough cuts and initial shaping, especially for large blocks of foam.

Other Essential Tools

Image by Joshua_Willson from Pixabay

Image by Joshua_Willson from Pixabay

Measuring Tapes and Rulers

Cost: £5 to £25

Usage: Precision is key in custom foam cutting, and measuring tools are indispensable.

Marking Tools

Cost: £1 to £10

Usage: Whether it’s chalk or specialized marking pens, you’ll need something to mark your cutting lines clearly.

Workbenches

Cost: Second-hand workbenches can range from £50 to £300.

Usage: A sturdy workbench is essential for laying out and cutting foam.

Safety Gear

Cost: £10 to £50 for a set that includes gloves, goggles, and a mask.

Usage: Safety first! Always use appropriate safety gear to protect against foam particles and blade accidents.

Conclusion

Getting into the custom foam bedding industry means an initial investment in the right tools. Choosing second-hand tools can be a cost-effective way to start, but ensure that you are buying quality, well-maintained equipment. With the right tools, your cut-to-size memory foam will be a cut above the rest.